Coldest Beer in Town, CIP Reporting with XLReporter

The cleaning and sanitizing of food and beverage contact equipment is critical. Preventing foods and drinks from being systematically contaminated by harmful bacteria that might become established on unclean equipment surfaces.

This is especially true the beer industry because the brewing process involves yeast. Yeast is a living organism that can easily contaminate an entire batch. As anyone who has a friend who brews at home and is a bit lax in cleaning their equipment, at best you get a funky tasting beer and at worst you get a day of solitude in the comforts of your own bathroom.

In industry, one of the most effective and efficient ways of cleaning this equipment is the Clean in Place (CIP) or Steam in Place (SIP) processes. These processes automate the cleaning of equipment with minimal dismantling of production equipment as well as the related production tools.

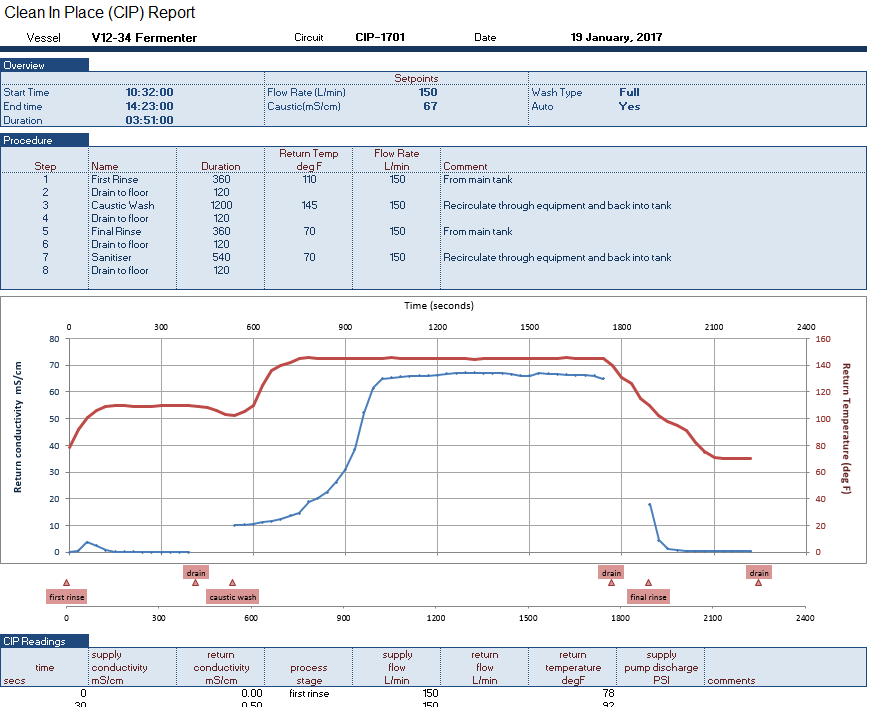

In order to remain compliant, the CIP process data must be recorded should any issues arise post production. Reports can contain live data from the process, sampled and calculated values from the historian. As well as, alarms from the database all together in a single report.

These reports prove compliance they can also be a reference to analyze the process to make it more efficient. Some studies have shown that with CIP data analysis, cycle cost, energy use and water user can be reduced by over 40% and cycle times by over 10%.

With a more efficient process, can produce more beer at a lower cost. Which in turn means cheaper beer for all!

For more information click here.